4 1 1 quantity weight or square area 4 1 2 name of material welded steel wire fabric for concrete reinforcement 4 1 3 wire spacing and sizes 4 1 4 length and width of sheets or rolls 4 1 5 packaging see section 18 and 4 1 6 astm designation and date of issue note 2 a typical ordering description is as fol.

Welded wire fabric reinforcement area.

Western welded wire fabric when used as a reinforcement as per is 1566 and with wires of fe480 grade is 432.

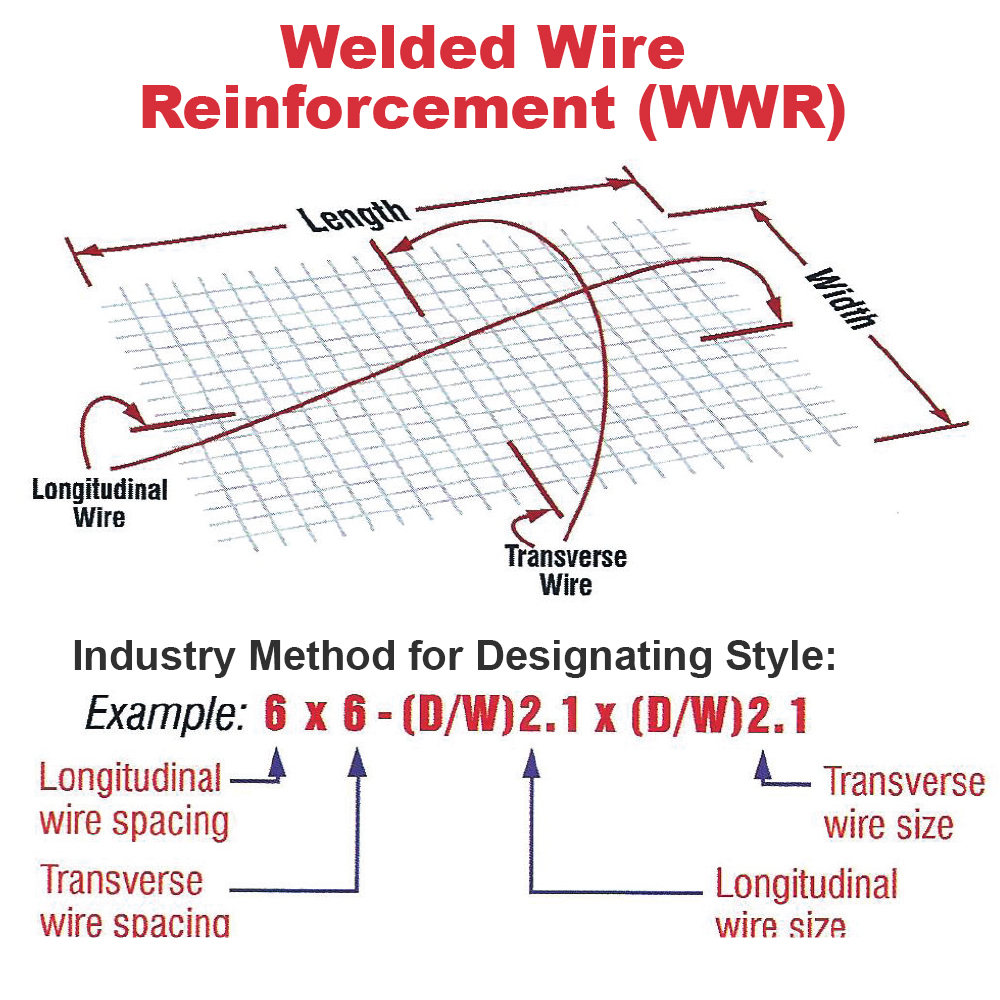

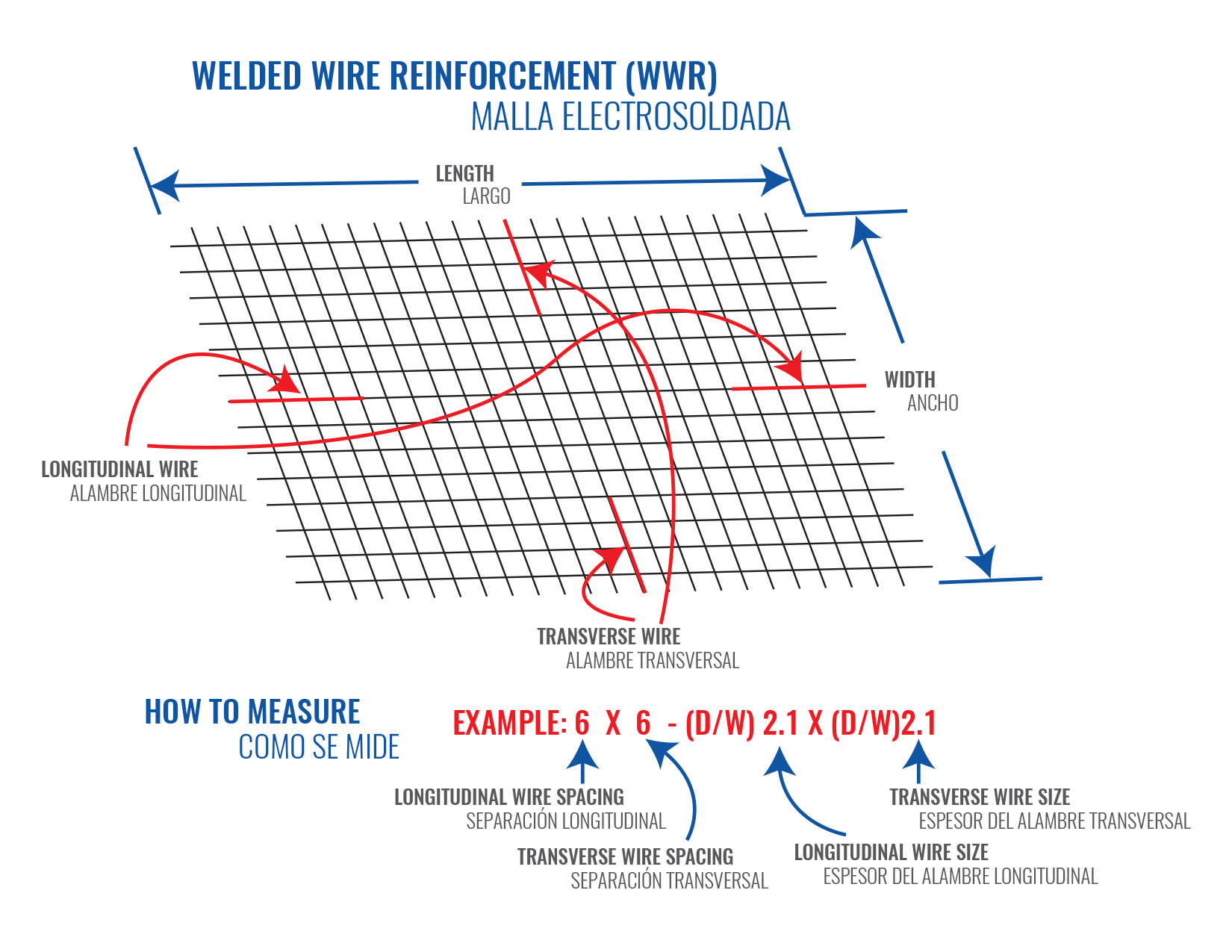

Concrete reinforcement style designation steel area weight new designation old designation sq.

Current designation by w number.

Sm o o t h welded wire fabric has a yield s t r ength of 65 000 psi and deform e d f a b r ic has a yield of 70 000 psi.

In the smooth fabric the smaller.

Exact w number size for 2 gauge is w5 4.

The bonding area of a close mesh fabric with welded joint s is several times.

Welded wire fabric is ava i l a b l e with either deformed or smooth w i re s as indicated earlier.

The cold rolled deformed wire used in welded mesh reinforcement fabric has a minimum characteristic strength 0 2 proof stress of 485 mpa compared to 450 mpa for high tensile rebar.

Common stock styles of welded wire fabric exact w number size for 8 gauge is w2 1.

2 ft area in.

Contact us on 0208 842 4855 to get a fast and competitive quote or discuss your requirements or contact us.

Deformed in space 4 in.

2 ft area in.

Common stock styles of welded wire fabric style designation.

Welded wire fabric of fers a saving of around 14 55 steel.

By w number by steel wire gauge longit.

Square mesh fabric a142 a193 a252 a393 below is our complete range of specifications for square mesh.

2 ft area in.

Welded mesh fabric reinforcement is manufactured using cold rolled deformed wire electrically resistance welded at the intersections of the longitudinal and transverse wires at the required mesh spacing with minimal loss of strength and cross sectional area.

Reinforcing fabric may be used at higher stresses than high tensile rebar resulting in material saving of up to 8.